Soil compaction is a very complicated and complex matter. It is all due to the fact that nowadays a very wide range of technologies is used with the greatest possible economic optimization. It is important to know that the choice of the method of soil compaction depends on many factors — ground conditions, technological possibilities and availability of materials among others. Soil compaction is sometimes necessary due to low bearing capacity and stability of the soil. The best compaction method can be selected by using an appropriate calculation method. Soil compaction is necessary when, after carrying out geotechnical research, it turns out that there are doubts concerning the load capacity of the soil on the plot intended for the construction of a single-family house. Unfortunately, many investors purchase plots of land and then immediately start to build the foundations. Later on, it turns out that the building erected on soil with poor bearing capacity is too prone to subsidence. As a result, dangerous cracks may appear on walls and floors.

It is best to entrust the geotechnical survey — i.e. soil investigation — to a specialised team which will issue an opinion based on the site measurements and laboratory analyses. The issued documentation will include data concerning ground water level, detailed maps with the places of performed tests and geotechnical cross-sections of boreholes. These documents will contain the most important information concerning bearing capacity of the soil.

It is worth emphasizing the fact that according to the provisions of the current construction law, it is not required to conduct geotechnical tests during the construction of a single-family house. Therefore, their performance is an individual decision of each investor. However, it might even be a good idea to perform geotechnical tests before purchasing a plot of land for construction. All because the subsequent soil compaction — if it turns out to be necessary — is usually very expensive, therefore the final cost of even a cheap plot of land may turn out to be very high. Fortunately, in our country stable grounds with high bearing capacity on which the construction of a single-family house is safe prevail. However, it is worth to check it before the construction begins in order to avoid unnecessary surprises later on.

To begin with, it is useful to define the types of building soils to know which ones are suitable for the construction of a single-family house.

The first criterion of division is the origin of grounds — here one may distinguish between native and embanked grounds.

The native ground is the ground created as a result of natural geological processes. Embanked soil, on the other hand, is the effect of human activity in a given area.

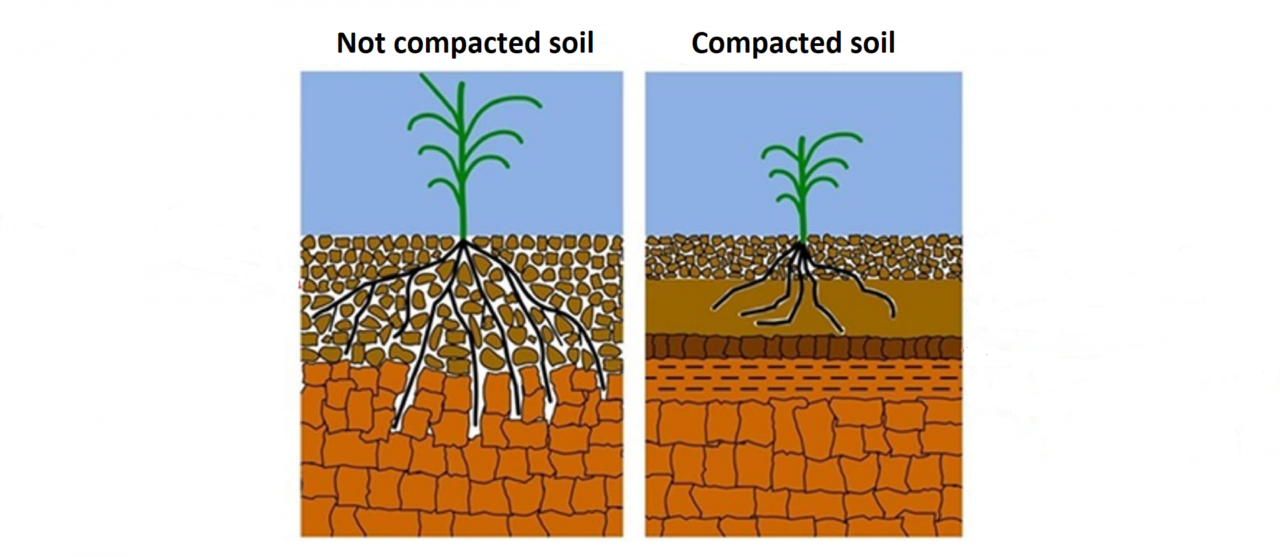

It is time to move on to the so-called cohesive soil. Non-cohesive soils, i.e. various types of gravels and sands of different density have different degrees of density — from loose soils to very compacted soils.

In some regions of our country, there are also cohesive soils which are suitable for building purposes only if they have a low plasticity level. The plasticity level depends on the water level in the soil. Cohesive soils can also be categorised from compact soils to liquid soils. If a cohesive soil is to be suitable for construction purposes, its plasticity index should not exceed 0.25.

It is also worth mentioning the native organic soils found in the country. You only need to know that in principle they are not suitable for construction purposes as the degree of compaction of such soil is very low and its bearing capacity is very limited. Therefore, when looking for a plot of land for construction, such soil is not taken into account at all.

So when does soil compaction for construction prove necessary?

As it has already been mentioned, in order for the foundations of a single-family house to be strong and durable, they should be placed on suitable soil. That is why it is always a good idea to carry out a geotechnical survey when planning the construction of a detached house. Despite the rather high cost, it is then easy to assess whether the soil is suitable or, on the contrary, needs strengthening. The research itself is much cheaper than subsequent compaction of the ground, therefore it is always worth opting for it.

Soil compaction methods

Soil compaction by means of columns — dynamic exchange method

In this method bucket excavators or various types of cranes drop a heavy rammer from a certain height. The first phase of the column formation in the compacted soil consists in breaking out a large crater and then — in filling it with aggregate. The aggregate column formed in this way is filled in by means of a special rammer, which is dropped again and again from a high height. The material filling the crater is replenished after each throw. These operations are repeated until the rammer caving in after the throw is significantly reduced. The increase of the caving resistance means that the base of the column has already reached the soil layer with higher stiffness. It is worth noting that the equipment used in this method is really impressive. This is because it makes it possible to drop a rammer weighing between 10 and 12 tons from a height of up to 40 m. In order to form one column on average 15 to 30 blows are needed. The stone columns significantly improve the soil parameters, i.e. among other things they compact the soil and improve its filtration.

Such stone columns may also be formed with the use of an impulse compactor. In this method a special punch forms a crater about 1 metre deep. It is then filled with coarse aggregate. This method differs from dynamic replacement in that it uses much less energy than a rammer falling from a great height. The resulting stone columns are much shorter, but much more precise and less time-consuming to make.

Impulse soil compaction

Soil compaction and improvement using impulse technology consists in applying high energy to a point in the area to be improved in a relatively short period of time. For this purpose a device is used which is mounted on a tracked chassis. This device has a specially constructed steel punch about one and a half meters in diameter. High energy is generated when a 9-tonne hammer strikes the stamp on the ground. It is launched from a height of about 1 meter with a very high density of blows per minute. The compactor moves over the entire compacted area according to a predetermined grid. Each point on which it stops requires a specific amount of energy to be transferred, adjusted to the local conditions.

Vibroflotation and vibrocompaction — compaction of soil with the use of gravel columns

Loose soils with too low compaction make it impossible to lay foundations on them. In case of such soils, a special vibrator is used which allows for increasing the compaction factor and leveling the ground. The type of the device used is selected depending on the type of soil. In this way its power and vibration frequency can be precisely selected. The device is attached to a crane or an excavator and thanks to the vibrations it can penetrate the ground. When the machine reaches the required depth it starts to rise and fall in a reciprocating motion while lifting very slowly. In this method the soil is compacted from the bottom, slowly reducing its porosity. The crater which is formed at the height of the ground is filled up with the transported material. The individual stages are completed when the vibrator is lifted to the ground surface. When the work with the vibrator is finished, it is necessary to level and compact the soil.

On the other hand, the vibroprobe is used in case of cohesive soils with too low mechanical parameters which are unsuitable for the foundations of a single-family house. A special sluice vibrator is used here thanks to which it is possible to insert gravel into the ground, which creates a special column. It is placed in the ground by means of vibrations created by the machine. The resistance and the speed of the column is continuously monitored. When the vibrator reaches the desired depth, it begins to form the column. The sluice at the bottom of the column opens and the aggregate is placed in the soil. When the vibration is finished, it is necessary to level the working level of the surface and further compact it with the surface vibrator.

Jet-grouting method

Jet injection, that is the jet-grouting method, is another soil improvement method based on mixing the soil with the grout pumped under high pressure. Interestingly, this method is currently used not only in civil engineering, but also in water engineering.

The works using this method are divided into two stages. The first one is drilling. A special rod is driven into the ground to the depth of the previously designed level of the base of the target column. During the drilling process a drilling rig is used to lift the excavated material to the surface.

The second stage of the works is forming the column. The cement slurry is pumped into the formed hole through the injection nozzles which are placed in the lower part of the rod. It is worth noting that the jet-grouting method works better in loose soils, where it takes less time and less material is used. If there are various obstacles in the ground, the shape of the created column does not have to be regular.

CFA Piles and Columns

Also used as a soil compaction method. A special auger plunges into the soil and slightly discharges the excavated material. This method allows for the fact that the surrounding soil does not loosen and the bearing capacity within the limits of the columns is significantly higher. In the central part of the auger there is a special duct which enables the concrete to be pumped during the forming process. This conduit is closed during drilling and opens when the auger reaches the desired depth. Low vibration and noise levels make this method suitable for use in the vicinity of existing structures. It works well on all types of loose and cohesive soils.

Surface stabilization

This is another method of soil compaction consisting in mixing in the optimal amount of binder and water. The purpose of cement which is added to the soil is to increase its cohesion, decrease its water absorption and its plasticity. The amount of the binder used depends on the properties which are to be achieved. The preparation of the substructure made of stabilized soil is divided into several stages. The first of them is the preparation of a suitable formula of the binding agent. Then, it is spread on the surface of the ground and mixed with soil with the addition of water. The resulting mixture is compacted with a smooth roller. After 7 and then after 28 days it is recommended that the soil be inspected.

Reinforced soil structures

Subsoil with low bearing capacity very often requires a structure consisting of a geotextile separation fabric, geosynthetic reinforcement and successive layers of reinforcement and aggregate layers. The most stable reinforced soil structures can be obtained by using geosynthetics. They ensure stabilization of aggregate grains by mutually wedging them. Geosynthetics may be used for the construction of various types of geomats or spatial structures which take the form of cells filled with aggregate.

Soil compaction and compaction factor

When we talk about the degree of soil compaction, we mean the natural state of the soil. This quantity characterises the soil which has been formed and deposited by nature. The soil compaction index, on the other hand, tells how compacted the soil that has been incorporated into the ground has been. This is an index that is only used for embankment soils, i.e. man-made soils. Both values can be accurately determined by laboratory testing and analysis. By compacting the same sample at different moisture contents, the volumetric density vs. moisture content curve can be determined. In this way the moisture content at which the maximum compaction of the soil is obtained can be determined. This test is very important because very often it happens that the soil is dried out and its compaction is very difficult to obtain.

The soil compaction index can also be determined by probing the soil. The most common and most frequently used device is a light probe. One should only remember that it should not be used to determine the soil compaction index to the depth of half a meter. Although some geotechnical engineers do this using correction formulas.

One of the most modern methods to quickly determine the compaction index is the light dynamic plate test. This is performed in the field. It is here that a dynamically loaded plate, which has an in-built sensor, allows to determine the dynamic modulus of elasticity of soil. It is on its basis that the degree of surface compaction can be determined. The great advantage of this solution is that the measurement takes only a few seconds and is very precise. The light dynamic plate can control the soil compaction to a depth of 30 cm. In order to test deeper soil layers it is necessary to perform test pits. Nowadays, light dynamic plate testing is becoming more and more common.

Price of soil compaction

Geotechnical work is indispensable when planning any construction work, because it is thanks to it that the area for construction can be properly prepared. In this way you can be sure that the planned single-family house will stand in a stable place with adequate bearing capacity. However, you have to be aware that geotechnical works and studies related to soil properties are quite expensive. However, they are of considerable importance as far as safety is concerned, which means that they are worth investing in the future. You should be aware that depending on the company or the type of service, the price of geotechnical works can vary greatly. Therefore, it will be best to consult with the contractors as this is the only way that you will gain an awareness of the amount that you will end up paying. In fact, two different companies can demand very different cm for the same service, so it is advisable to do a little comparison first before you decide on the service of a particular company.

In order for a building to be erected on the chosen site, the ground must be properly prepared for it. With proper reinforcement, the ground will be able to bear much more weight than before the work was done. Of course, the price for these works will depend on the region, the company, the size of the site and the type of reinforcement that will be necessary. The price is very difficult to determine because it is very much an individual issue. It depends not only on the number of boreholes in the ground, but also on the choice of the method to be used.

You can of course find basic price lists on the websites of various geotechnical companies. Usually, however, the final price depends on the size and type of job anyway. You need to be prepared for the fact that soil compaction will not be the only expense that will be necessary. The geotechnical testing itself, which allows you to determine the type and specification of the soil in general, is already quite expensive. It is the opinion which will determine whether the soil compaction works will be necessary at all.

To sum up, despite the fact that the majority of building grounds available in UK usually have a proper bearing capacity, it is always worth to perform a geotechnical survey which will tell whether this is really the case. Here it is worth following the rule that prevention is much better than curing the consequences of negligence later on. After the completion of the investment on the ground of poor bearing capacity, intensive subsidence of the building may occur, which may even end with a disaster. Therefore, it is always worth considering soil compaction if there is a suspicion of poor bearing capacity and high groundwater level. You can determine this very often just by the fact that all houses in the area are built on elevated ground. It is also worth remembering that geotechnical examinations can be done even before buying the ground. Yes, they are quite expensive, but they still cost less than compacting the land. It may turn out that a plot of land offered for sale at a very attractive price has poor bearing capacity, which means that compaction may be necessary. Then it may turn out that the attractive price was only a pretence.

The type of soil which most often turns out to be necessary for the compaction is the one made of sand, gravel with a low content of dust fraction, asphalt, as well as degraded areas — i.e. anywhere where mining, communal or energetic waste is deposited.

Probably nobody needs to be reminded that the construction of a single-family house is a very expensive undertaking. Therefore, it is a pity to waste all the money invested to build it on uncertain ground. That is why it is worth ensuring that the soil has the best possible bearing capacity, which is possible precisely thanks to compaction. Compaction protects not only the interests of the investor, but also of the contractor. Thanks to the compaction you can be sure that after some time the construction will not settle and there will be no construction disaster. Even in the least risky variant of erecting the building on unstable ground the walls and floors will end up cracking.

In summary, compaction is a technological process which increases the volumetric density of the soil. This improves other soil parameters such as porosity, bearing capacity, shear strength, water and frost resistance and water permeability. Loose soil, due to its own weight and external influences, will begin to compact naturally after some time. In this way the subsoil will settle and the entire structure will follow. The main purpose of the soil compaction is to eliminate this threat and thus to ensure that the house which will be erected will be safe.

It is very often said that the basis of a solid construction of any single-family house is a strong and durable foundation. Not everyone is aware of the fact that if they are put on unsuitable ground, they won’t be worth much in reality. Therefore, it is safe to say that the foundation of any single-family home is the compact and stable ground on which it will stand. No matter what methods are chosen — tamping, jet-grounding or cement mortar injections — they ensure that the foundations of the structure will be safe in the future. It must be remembered that the soil compaction method, or actually its selection, does not depend only on the investor’s will. It is on the basis of geotechnical research that it is determined which type of soil compaction will be the most suitable for the given surface.

Many people deciding on soil compaction do not know what costs they should prepare for. In order to do so, it is worth finding a company that will not only guarantee to minimize them, but also provide a top quality service. Of course, finding such a company will be easiest if you use the internet. However, you need to be prepared to know the cost of the service not immediately. The contractor will have to make a detailed cost estimate, based on the type of land, its area, as well as other important factors. The builder must prepare for the fact that soil compaction is a rather expensive process, but in some cases — it cannot be avoided. The necessity of soil compaction can be avoided, as it has already been mentioned above, at the stage of plot purchase. Geotechnical research makes it possible to resign from purchasing an unstable ground which will require compaction in the future. Despite the fact that current building regulations do not require geotechnical tests to be performed before the construction of a single-family house begins, it is definitely in the investor’s interest to perform them. After all, once the single-family home is erected, it may turn out that if compaction was necessary and not performed, there is really nothing that can help anymore.

In conclusion, compacting land for the construction of a single-family house is a matter of prudence and taking care of your future interests. After all, it may not be possible to repair any damage that may occur later. In the best case scenario, erecting a house on an inadequately prepared ground may end up with cracking of walls and floors. It is better not even to speak about the worst variant — intensive subsidence may end up with complete destruction of the building. As mentioned above, there are many methods of soil compaction and they must be adjusted depending on the existing circumstances. This text should make it clear to investors who are still thinking about doing a geotechnical study that, in fact, there is nothing to think about. For only a detailed analysis of the surface is able to show whether the planned construction will stand firm and be safe.

In conclusion, there is still not enough said about geotechnical investigations and soil compaction and it is an issue which every investor should know in detail. Fortunately, unstable soils are still rare in UK, so soil compaction is needed in really exceptional and rare cases.

FAQ

When is soil compaction necessary?

The bearing capacity of the soil is of crucial importance during construction works. An analysis of the subsoil clearly indicates the quality and determines whether the soil is sufficiently cohesive. If there is a risk of settlement, the soil must be compacted.

What types of construction soil are there?

Building ground can be divided into: natural ground and anthropogenic ground.

What are the ways of soil compaction?

Depending on the complexity of the problem, the following methods are used: column compaction, impulse compaction, vibroflotation and vibroflotation, jet injection.